Blog should have at least one update weekly (what we did

that week, what went well, what our problems were).

Report 3: (not due this Wednesday)

Make the molds: Do they work? Do we have to redesign it?

If yes: We redo report two.

Redo ghant chart? Nope.

Clothing:, underwear and socks.

Parts (progress/who):

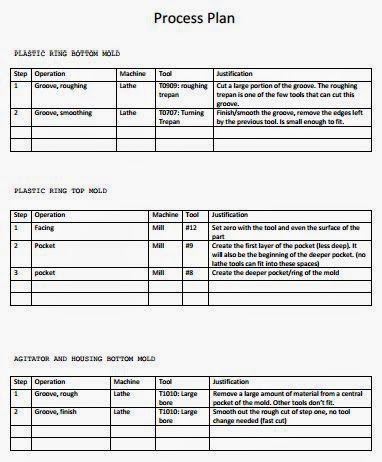

Top Ring (Andrea/Tyler/Ola)

Inner Ring (done)

Bubble (done)

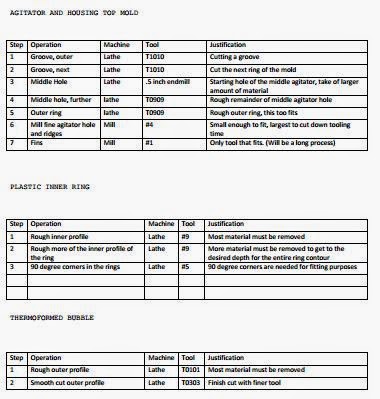

Housing/agitator (Chee/Doug)

Clothes (Andrea/Jody)

To Do (By Tuesday):

n

Redesign SW of yoyo and molds (make the top

ring turnable [increase channel width to fit tools, minimum 0.08], increase the

circumference of housing to be flush with the upper ring, redo the agitator to

be thicker and shallower. Make sure to add fillets. Insert screw/nut hole)

o

Need to get the dimensions of the screw we’re

using.

n

Mastercam:

o

Agitator/housing (Chee and Doug work on this)

o

Top ring (Andrea/Tyler do the lathe, Ola is

doing the milling/engraving))

Tuesday:

n

Give the Daves our list to order (O-ring,

material for clothing)

n

Go over mastercam, redo if needed.

Wednesday

n

Machine all the molds